樹脂用潤滑剤

さまざまな樹脂部品のパフォーマンスを最大化

特長

- 樹脂(プラスチック)に対して優れた耐摩耗性を発揮するため、動作を伴う樹脂部品の摩擦を減らし、摩耗を抑制し、部品の長寿命化に貢献します。

- 多くのゴムや樹脂(プラスチック)に使用可能であるため、ゴムや樹脂に悪影響を与えません。

特性

樹脂は、軽量化のニーズの高まりや材料技術の進化により、ギヤなどの機械要素への使用機会が増えています。樹脂は一般的に摩擦係数が小さいため、無潤滑で使用される場合もありますが、潤滑剤を使用することでさらなる摩擦・摩耗の低減が可能になります。ただし、樹脂に潤滑剤を使用する場合は、悪影響を与えないものを選定する必要があります。樹脂に悪影響を与えず、樹脂部品のパフォーマンスを最大化する樹脂用潤滑剤をラインアップしています。

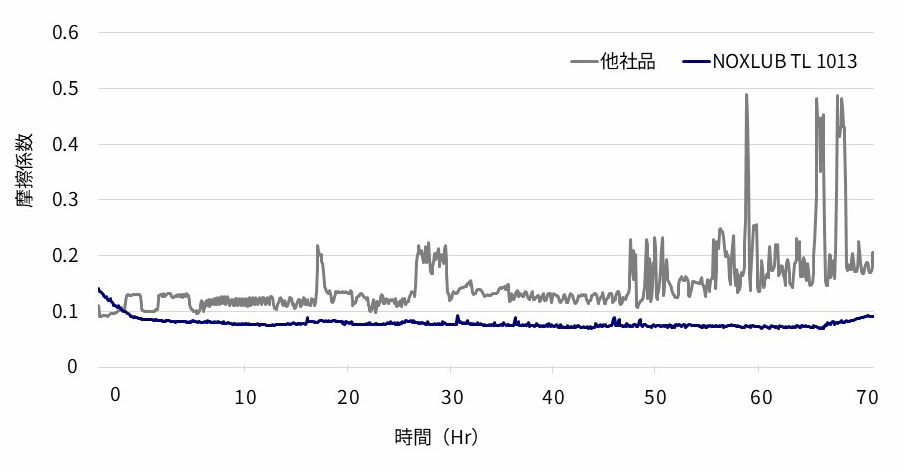

評価試験

振動摩擦摩耗試験

振動摩擦摩耗試験機を用いて、樹脂同士が動作した際の摩擦係数を測定し、潤滑状態の確認を行いました。

試験結果によると、他社製品は試験全体を通して摩擦係数が安定しておらず、試験時間50時間を経過した後は特に摩擦係数が不安定になる結果が得られました。

「NOXLUB」※ TL 1013は、他社製品と比較して摩擦係数が低く、また安定している結果となりました。

「NOXLUB」TL 1013を使用することで、樹脂部品の低摩擦化、摩耗抑制、長寿命化が期待できます。

※「NOXLUB」は、NOKの登録商標です。(商標登録1625094、5652781号)

【試験条件】

接触形態 : 線接触/すべり

試験材 : POMシリンダ、POMディスク

負荷 : 20N

温度 : 室温

振動数 : 20Hz

振幅 : 2mm

時間 : ~70Hr

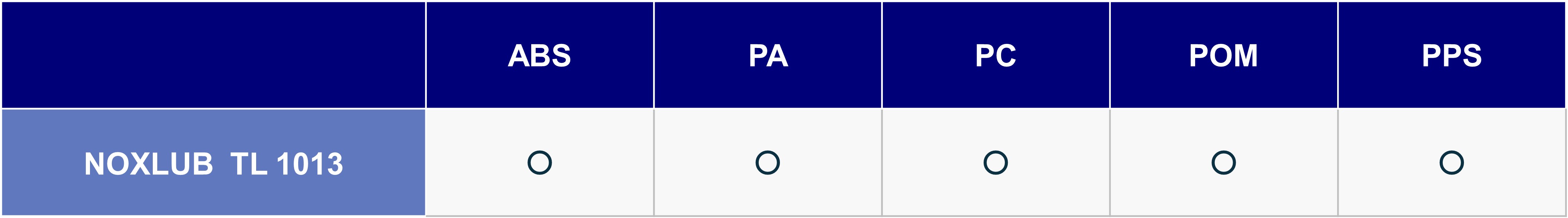

樹脂応力試験(オリジナル)

潤滑剤と樹脂の相性を確認するために、樹脂応力試験を実施しました。

樹脂試験片(100mm×25mm×2mm)の中心部が高くなるように円柱を設置し、試験片に応力を加えました。

応力部に潤滑剤を塗布し、室温で乾燥させた後、70℃の恒温槽内に100時間静置しました。

静置後、外観状態から割れやクラックの有無を確認し、潤滑剤と樹脂試験材との相性を確認しました。

「NOXLUB」TL 1013は、実施したいずれの樹脂においても割れやクラックの発生がありませんでした。

活用例

- コピー/プリンターなどのOA機器のプラスチックギヤ、自動車補機/電装品のプラスチックギヤ、消音を目的としたプラスチックギヤ/プラスチック部品

製品ラインアップ

-

クリーンルーム用低発塵グリース

クリーンルーム内の清浄度を保ち、潤滑性にも優れるクリーンルーム用低発塵グリース

-

アルミ腐食防止グリース

嵌合部などに塗布することで、微小な隙間を埋めアルミのスキマ腐食を防止

-

極低温フッ素グリース

マイナス80℃の極低温環境下でも流動性を保ち、特性を発揮

-

自動給脂装置

自動で給脂し、メンテナンスを省力・省人化

-

転がり軸受用潤滑剤

特殊環境でのさまざまなニーズに応える

-

真空・半導体用潤滑剤

業界トップレベルの低アウトガス性で高真空環境下の製造に

-

シール・パッキン・Oリング用潤滑剤「SEALUB」※

シール製品の組み付け性を向上

-

ギヤ用潤滑剤

耐荷重性と耐摩耗性で、ギアの長寿命化を実現

-

食品機械用潤滑剤

NSF H1 登録 200 種類以上、食の安全性をより確かに

-

潤滑スプレー製品

錆止め、離型剤、グリース、オイル、組み付け剤、固体潤滑剤などのスプレータイプ

-

固体被膜潤滑剤「グライトパン」※

金属面に被膜を形成し、基材の機械的特性を維持

-

工作機械用潤滑剤

オイルミストの発生を抑制し、作業環境を改善するグリース

-

チェーン用潤滑剤

高性能な合成油を使用し、チェーンの摩耗を防ぐ

-

電気・電子機器用潤滑剤

接接点部分の摩耗を防ぎ、耐久性を向上

-

樹脂用潤滑剤

さまざまな樹脂部品のパフォーマンスを最大化

-

生分解性潤滑剤

二酸化炭素と水に分解され、環境負荷を低減

-

防錆・離型潤滑剤

高い浸透性と錆止め性を有する

-

ロボット用潤滑剤

優れた耐摩耗性で耐久性を向上し、メンテナンス頻度を低減

-

焼結含侵軸受用潤滑剤

低温性に優れ、起動トルクが小さい

-

バルブ・コック用潤滑剤「UNISILKON」※

耐水性、耐スチーム性、耐熱性を兼ね揃え、給水装置にも使用できる安全性

-

組み立て用潤滑剤

ボルトの固着や焼き付きを防ぐ

-

蓄電池用潤滑剤

水分量を抑え、低露点環境での使用に最適

-

コンプレッサ用潤滑剤

各種ガスに対し、優れた耐性と酸化安定性を持つ

-

風力発電設備用潤滑剤

高い耐荷重性と潤滑性で、設備の長寿命化を実現

-

食品機械コンプレッサー用オイル

食品グレードで安全であり、酸化劣化によるスラッジの発生を抑えた長寿命なコンプレッサー油

-

食品機械軸受用グリース

耐熱性に非常に優れた食品機械用グリースで、装置のダウンタイムコストやメンテナンスコストを削減

-

多用途型 食品機械用グリース

耐熱性・付着性・耐摩耗性・耐水性に優れ、様々な過酷環境で使用できる多用途型の食品機械用グリース

※「SEALUB」はNOKクリューバーの登録商標です。 (商標登録5652781号)

※「グライトパン」はNOKクリューバーの登録商標です。 (商標登録5552576、5552577号)

※「UNISILKON」はKlüber Lubrication München GmbH & Co. KGの登録商標です。(商標登録3140009号)

お問い合わせ

製品の詳細はNOKクリューバー株式会社のWebサイトをご覧ください。